Colour Coded Cleaning – What You Need to Know

Colour coded cleaning is one of those cleaning tricks that you’ve probably encountered without realising it.

Cleaning professionals across all industries know the value of colour coded cleaning equipment which can be easily identified and utilised by all staff. But what is colour coded cleaning and how can it help you?

What is colour coded cleaning and why is it important?

It’s worth pointing out that colour coded cleaning for cleaners might not be legally required, but it’s widely used by cleaners and businesses to create a safer operational environment. The British Institute of Cleaning Science (BICS) recommend the use of colour coded cleaning equipment to ensure hygiene standards. It can stop cross-contamination between areas of a business that shouldn’t share cleaning equipment, such as the bathrooms and the kitchen.

The system works with 4 different colours highlighting to employees which equipment should be used where. So why is cleaning equipment colour coded? A colour coded cleaning equipment list can be the first line of defence in protecting the hygiene standards of any commercial location.

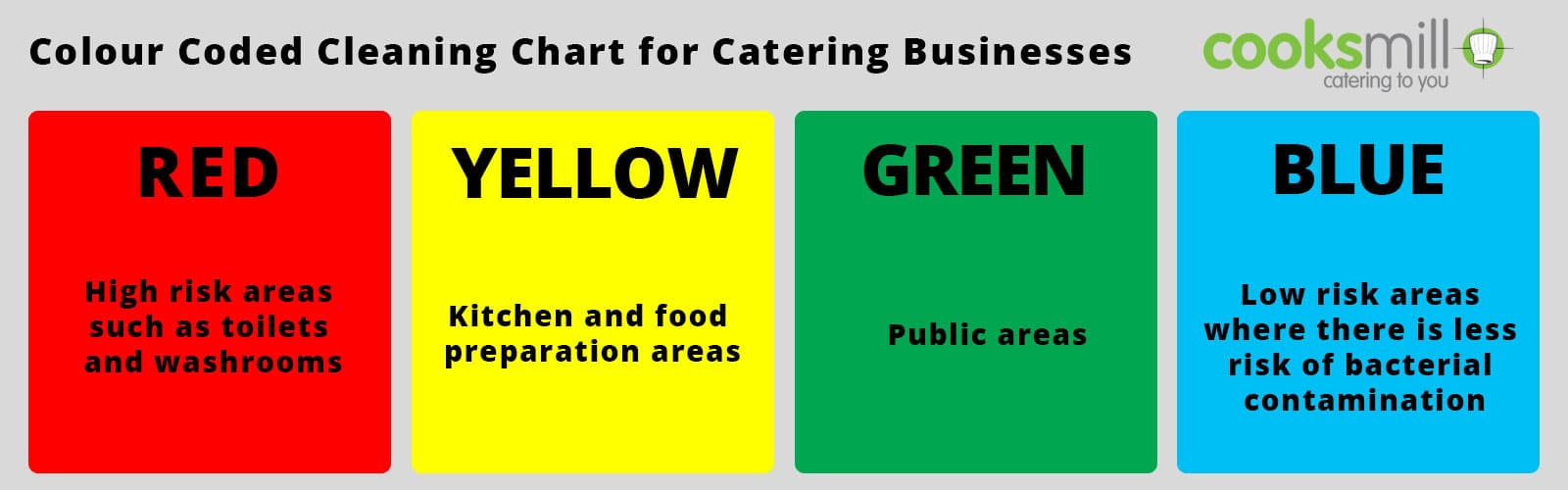

What are the 4 colours and where are they used?

There are 4 colours involved in colour coded cleaning which splits a commercial location into 4 distinct areas where cleaning equipment shouldn’t be cross-contaminated. If a colour coded cleaning chart is followed effectively by all employees, hygiene risks will be minimised, and the integrity of a cleaning process will be maintained.

These are the 4 colours to be aware of:

- RED

- YELLOW

- GREEN

- BLUE

It’s important to realise that coloured cleaning for restaurants and other catering facilities has significant differences to the general colour coded cleaning charts you might see for locations such as healthcare and industrial cleaning. In those charts, yellow is generally used to denote clinical cleaning equipment, while green denotes food preparation. As kitchens are a specific working environment with important hygiene rules, yellow becomes specific to food preparation areas, and that’s something to be aware of when you’re looking at colour coded equipment. We have created a cleaning colour code chart (UK) below to help you select your colour coded cleaning supplies.

Colour coded cleaning chart for catering businesses

While there are no legal rules for colour coded cleaning for kitchens and other catering locations, there are conventions used across the industry which help employees navigate their way effectively around businesses of similar types. Colour coding for kitchen cleaning ensures the appropriate equipment for any task can be located rapidly and will be used correctly.

DOWNLOAD OUR COLOUR CLEANING CHART HERE

In a catering environment a colour coded cleaning chart might comprise:

- RED – High risk areas such as toilets and washrooms

- YELLOW – Kitchen and food preparation areas

- GREEN – Public areas

- BLUE – Low risk areas where there is less risk of bacterial contamination

While it’s feasible for a catering company to use their own colour coded cleaning system, most opt to use the widely accepted version as this reduces the risks of cross-contamination and other hygiene issues that might arise.

Common colour coded cleaning equipment list

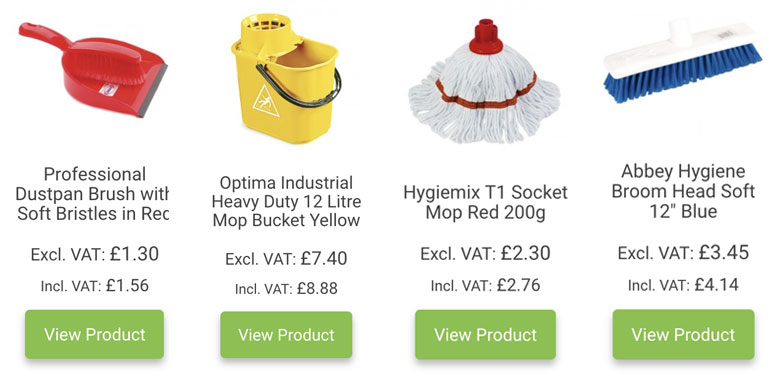

Various pieces of colour coded cleaning equipment are available to help you run your catering facility effectively. While anything could theoretically be colour coded for ease, there are several pieces of critical equipment that are often used in colour coded cleaning for cleaners.

- Colour Coded Mops – Avoiding cross-contamination of bacteria during mopping is important to maintain hygiene standards across a facility. Mops can easily hold germs in their fibres, so keep colour coded mops for every area of the facility.

- Colour Coded Mop Buckets – Similarly, mop buckets should be coordinated with mops and should never be mixed with each other. Keeping a colour coded cleaning chart will ensure that mops and buckets aren’t intermingled.

- Colour Coded Brushes & Dustpans – Just like mops, the bristles of brushes can cause a health hazard if they’re used in the wrong environment. Coordinate with a colour coded dustpan for maximum protection.

- Colour Coded Cloths – Cloths can harbour germs that are easily transferred between areas if strict colour coded cleaning isn’t adhered to. Purchase a large supply of colour coded cleaning cloths to ensure you won’t be tempted to cross-contaminate or use the wrong coloured ones.

Staff training & implementing colour coded cleaning

To adhere to best practice, catering businesses should implement colour coded cleaning for cleaners and other members of staff that is built into the ethos of the company. Managers should ensure that colour coded cleaning equipment is not only available but also utilised to its fullest extent.

Make colour coded cleaning practices part of every employee’s induction and use signage wherever necessary to promote the use of your colour coded cleaning equipment list. One major benefit of the colour coded cleaning system is that it’s a highly visual one – employees only need to grasp the basic differentiation of the four colours and their use in a catering environment for the system to operate. Sticking to the industry recommended coloured cleaning for restaurants and other catering locations will also help employees to move between roles easily without compromising on standards.

Where else is colour coded equipment used?

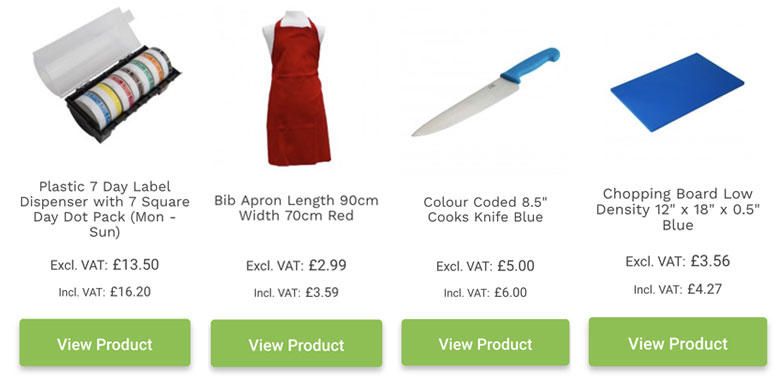

Elsewhere in the catering industry, you’ll find colour coded equipment used to keep hygiene levels high and to reduce the possibility of cross-contamination during food preparation. These are just some examples of where colour coding comes in useful beyond the cleaning cupboard:

- Chopping Boards – Just as with cleaning equipment, there is a hierarchy of chopping board colour coding that adheres to the approximate colours of the food for ease of use. Again, high risk raw meat is denoted by a red chopping board, with raw fish using a blue one and cooked meats, salads/fruits, root vegetables and dairy products using yellow, green, brown and white respectively.

- Knives & Utensils – The pattern for knives and utensils follows the established pattern for colour coded chopping boards as described above.

- Food Labelling – Colour coded labelling systems can be used to specify the days foods must be disposed of, ensuring that only safe foods remain stored in fridges and no cross-contamination occurs.

- Clothing – Some large catering locations colour code their staff clothing to make it easier to identify who works with what team and what their role is. This can take the form of coloured aprons as well as more complicated uniforms.

Colour coded cleaning equipment from Cooksmill

For all your colour coded cleaning equipment needs, look no further than Cooksmill. Not only do we have a superstore in Manchester, we also have a huge online shop with over 20,000 products available and FREE delivery on offer for all orders over £50 (excluding VAT). Visit the Cooksmill online shop today, whether you’re looking for colour coded cleaning for kitchens or any other type of colour coded equipment.

If you have any equipment questions or need a hand with your order, feel free to give our friendly team a call or email us via info@cooksmill.co.uk.

Sign up to Cooksmill's Newsletter!

Receive all the latest offers, competitions, new products, and current blogs.