Buyer’s Guide To Restaurant Cutlery From The Experts At Cooksmill

Owning and operating any restaurant or cafe entails lots of different buying decisions, and this guide helps inform restaurateurs, hoteliers, and cafe owners about the types of stainless steel and the way cutlery is manufactured. Choosing cutlery to suit your establishment will mean making value decisions, as it's generally a good idea to pair cutlery with the type of menu on offer. That way diners use all their senses while eating and can learn to appreciate what could be considered the more subtle benefits of gourmet dining, for example.

To start off, we'll take a quick look at the different types of stainless steel and the cutlery manufacturing process. Then we'll move on to discuss the cutlery line up offered by Cooksmill, alongside the business benefits of shopping with us.

Different grades of stainless steel used for restaurant cutlery

One of the first things you'll notice when shopping for restaurant-quality cutlery is the 18/0 and 18/10 classifications and also how prices in each class differ immensely. These classifications relate to the type of stainless steel contained in each product. Stainless steel is a manmade alloy, so it can contain two or more different metals. This makes it an ideal metal for cutlery, as different classifications can be used to suit any type of dining establishment.

The definition of the two different classifications is as follows:

18/0 Cutlery

The number "18" relates to the chrome content of the product and is measured as a percentage of weight. The chromium component of stainless steel adds the shiny, stainless property to the metal, and also makes it resistant to rusting or oxidation. An added benefit of the chromium content is that it always looks fantastic after polishing.

The "0" in 18/0 cutlery indicates that no nickel has been added to the product. What this means is that the cutlery retains its magnetic quality, which is perfect if you operate a high volume restaurant utilising one of the magnetic cutlery saving methods. Explore 18/0 Cutlery

18/10 Cutlery

The only difference between 18/0 and 18/10 classified cutlery is that nickel has been added to the mix in 18/10. Again, the "10" indicates the amount of nickel as a percentage by weight. This type of cutlery has even more protection against corrosion and pit marks, however, it is generally more expensive due to the high costs of nickel. Explore 18/10 Cutlery.

Manufacturing processes for restaurant-grade stainless steel cutlery

Now you know about the types of stainless steel used for restaurant cutlery, you'll probably want to know the difference is between pressed, forged, and buffed.

Pressed and forged cutlery

The shape of all cutlery comes from the methods used in manufacturing. In the pressed cutlery sector, products are made from one huge sheet of stainless steel. Although this makes it easy to add different patterns to any product, it also means most pressed cutlery has fairly different shapes. Take the time to look at all the different cutlery styles and patterns in our Olympia Parish Pattern line up to see just how different pressed cutlery can actually be.

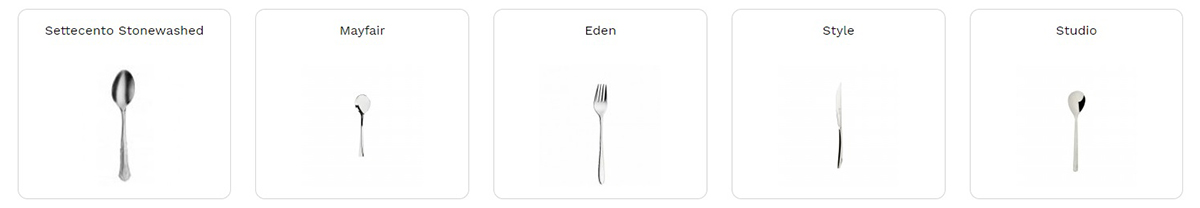

Forged cutlery, on the other hand, is made from solid stainless steel bars which are hammered into shape. This makes it easy to create oval, square or round shaped cutlery, but does limit any patterning on products. The Viners Mayfair dessert spoon design is an excellent example of the sort of rounded shape and high polish that can be attained using 18/10 stainless steel.

On the whole, the different ranges of forged cutlery you can buy will tend to be fairly plain in design, but their shapes make them stand out. Forged cutlery manufacturing is very labour intensive, so it will be more expensive than any stamped products.

Buffing

The buffing categorisation for stainless cutlery refers to the finishing polish during manufacture. The inexpensive lines of cutlery just tend to be tumble finished via four buffing processes. The silky sheen on fine 18/10 grade cutlery, however, may often only be acquired after 27 buffing procedures. This fine finish even extends to buffing between all the prongs of forks! That's one of the reasons fine quality steak knives and forks are available at so many different price points. And, we're quite sure you can more easily recognise just how the finest cutlery can complement your table, while also adding increased enjoyment for diners (insert link).

Why choose Cooksmill for all your commercial cutlery?

One of the major benefits of buying restaurant standard cutlery from Cooksmill is that you don't have to purchase our products in sets. This is hugely beneficial to commercial restaurants because it enables them to build their cutlery sets to suit the menu. For example, if you don't serve soups at all, the soup spoons within any commercial set are a total waste of money. Take the time to browse our entire cutlery line up now - we're proud of the wide variety of quality cutlery products we supply, whether you're looking for economy cutlery or you're seeking premium 18/10 products.

Here at Cooksmill, we have an exciting range of unique food service products plus exciting accessories that will make you stand out from the crowd. To learn more then simply visit our website today to shop online or visit our Manchester store. Delivery is free on orders over £50 ex vat with thousands of items available for next day delivery when you shop online.